0538-5089056

0538-5089056

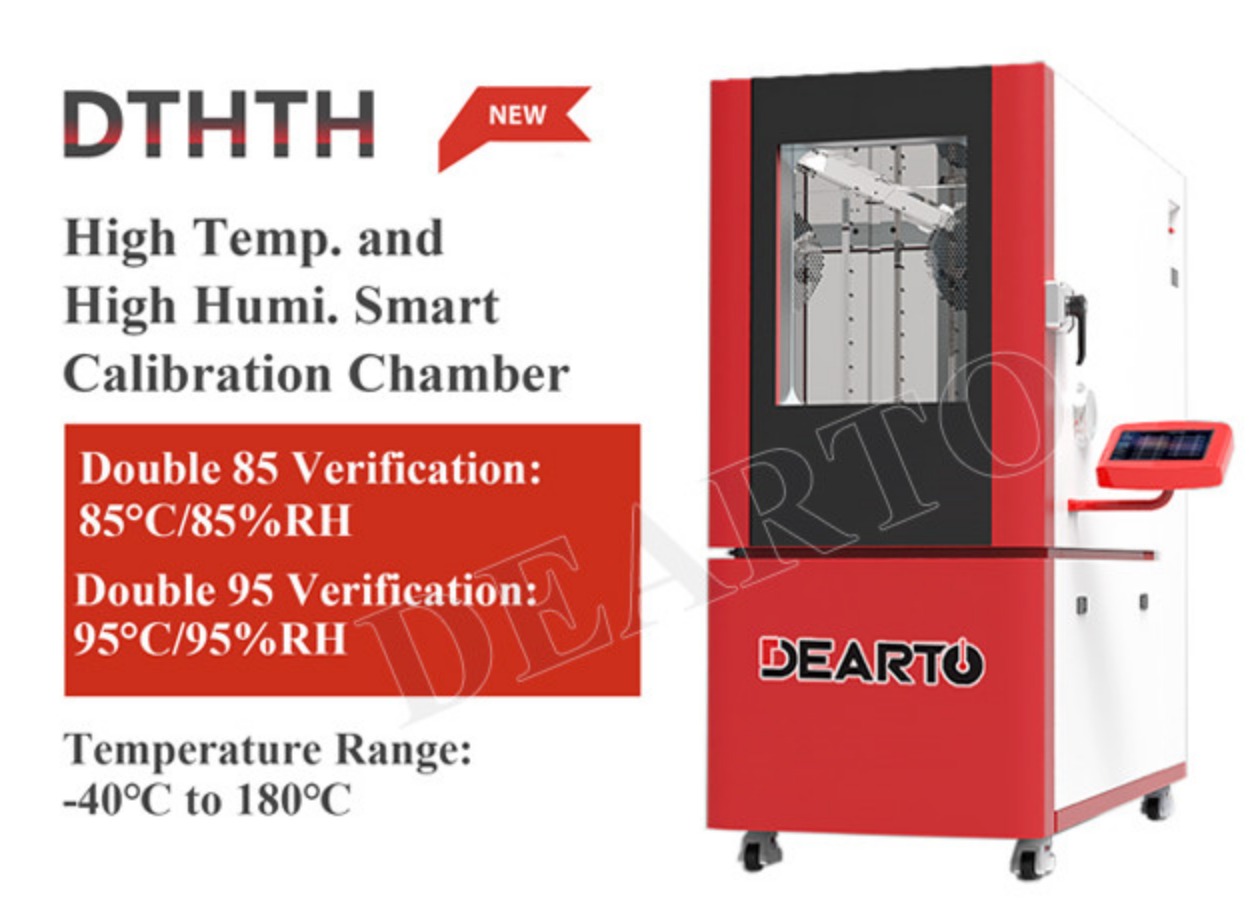

What can DTHTH high temperature & high humidity calibration chamber be used to do?

"Dual 85" (85°C / 85% RH) and "Dual 95" (95°C / 95%RH) temperature and humidity calibration chambers are primarily used for highly accelerated damp heat stress testing. Their purpose is to simulate harsh humid and high-temperature conditions in a laboratory environment to rapidly evaluate the reliability, durability, and potential failure modes of electronic products, materials, components, coatings, etc., under long-term humid and hot conditions.

Their key applications and objectives include:

1.Electronic Components & Assemblies (especially semiconductors):

Assessing Moisture Resistance: Testing the moisture barrier capability of component packaging materials (e.g., IC chips, resistors, capacitors, connectors) and corrosion resistance of metal parts (e.g., leads, solder joints).

Accelerated Life Testing (ALT): Predicting the long-term reliability of components under normal operating environments (e.g., tropical/subtropical climates or inside sealed electronic devices). Damp heat accelerates multiple failure mechanisms, such as:

Electrolytic corrosion (e.g., aluminum wire corrosion).

Intermetallic compound growth.

Package delamination.

Moisture-induced cracking in mold compounds ("popcorn effect").

Conductive anodic filament (CAF) growth.

Process Validation: Verifying if packaging, cleaning, and other processes effectively resist moisture ingress.

Screening: Quickly identifying and eliminating early-failure or latent-defect components (use with caution, as high stress may introduce non-relevant failures).

2.Printed Circuit Board Assemblies (PCBAs):

Evaluating Solder Joint Reliability: Testing the mechanical strength and fatigue resistance of solder joints under damp heat cycling or steady-state conditions.

Testing PCB Substrates & Solder Masks: Assessing moisture absorption, resistance to delamination, dimensional stability of base materials (e.g., FR4), and the adhesion/insulation properties of solder masks.

Verifying PCBA Cleaning Effectiveness: Residual ionic contaminants can readily cause electrochemical migration and corrosion under high temperature/humidity.

3.Materials (Plastics, Polymers, Coatings, Adhesives, etc.):

Assessing Hygroscopicity: Measuring water absorption rates and dimensional changes (swelling) of materials in high-humidity environments.

Testing Thermo-Hygroscopic Stability: Evaluating the retention of mechanical properties (strength, modulus, toughness), color stability, transparency changes, etc., under high temperature/humidity.

Evaluating Hydrolysis Resistance: High temperature/humidity accelerates hydrolysis in certain polymers (e.g., PET, nylon, polyesters, polyurethanes), leading to chain scission and performance degradation.

Testing Coating/Plating Adhesion & Protective Properties: Verifying the resistance of coatings (paints, powder coatings) and platings (zinc, nickel, etc.) to blistering, peeling, and corrosion under damp heat.

Testing Adhesive Durability: Assessing bond strength retention and failure modes of adhesives in humid/hot environments.

4.Automotive, Aerospace, & Military Electronics:

These sectors demand extremely high reliability. Dual 85/Dual 95 testing is a common method to validate whether critical components (e.g., electronics in engine compartments, avionics, military comms equipment) can withstand extreme humid/hot environments (e.g., rainforests, maritime settings).

| Previous:DTMA-101G protable high precision thermometer, specially designed for SPRT/PRT/RTD |

Headquarter Address :Tai'an High-tech Development Zone, Shandong Province

Headquarter Address :Tai'an High-tech Development Zone, Shandong Province

Telephon :+86 0538-5089056 +86 13953856217

Fax : +86 0538-5059718

After sale:+86 0538-5050959

Website : www.tadt.com.cn

E-mail : tadtzdh@dearto.cn

Copyright© Tai'an Detu Automation Instrument Co., Ltd. Lu ICP 14024757-1